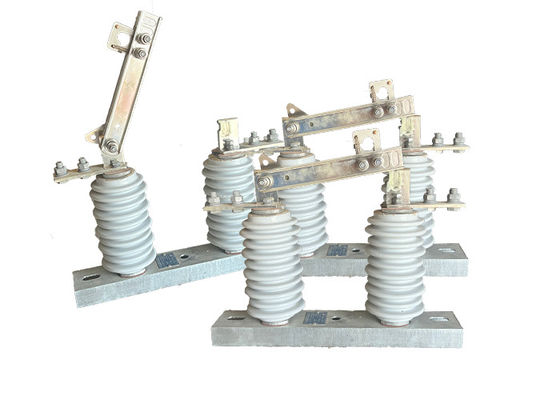

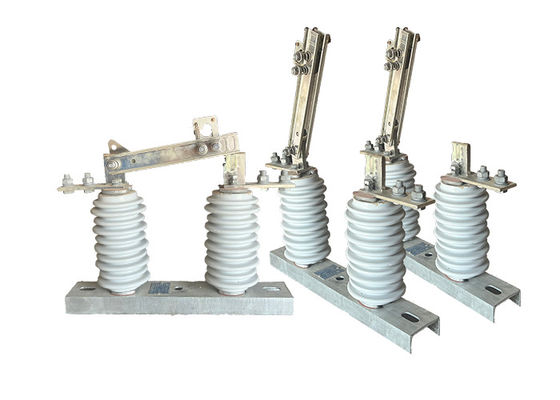

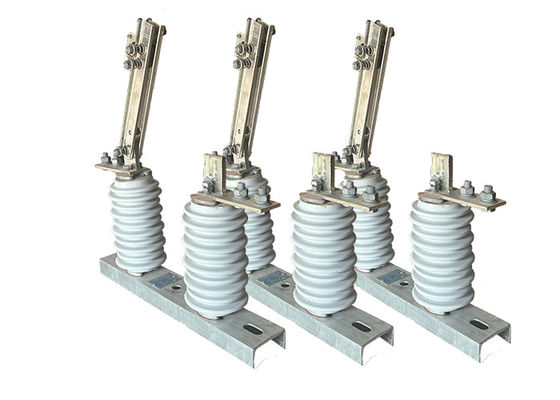

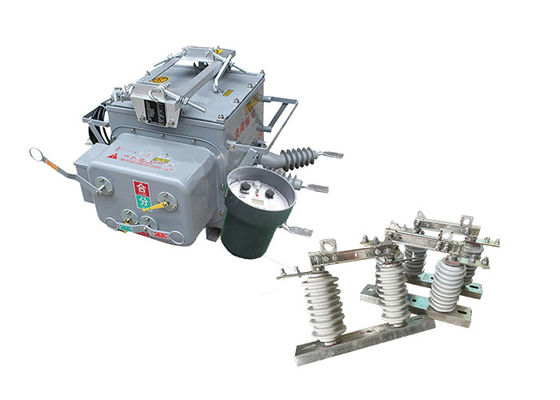

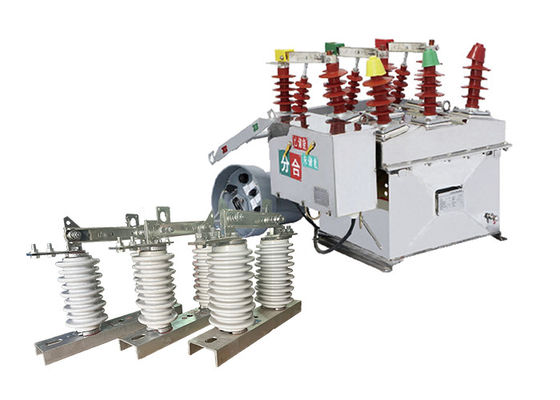

New Design GW9 Series Outdoor Disconnector Switch Quickly Opening/Closing Portable Hookstick Operated Switch

Product Description:

Outdoor disconnector switches are indeed used in high-voltage power transmission and distribution systems to disconnect circuits from their power sources for maintenance or repair purposes. They provide a means for isolating the circuit from the power supply, allowing workers to safely perform their tasks without the risk of electric shock.

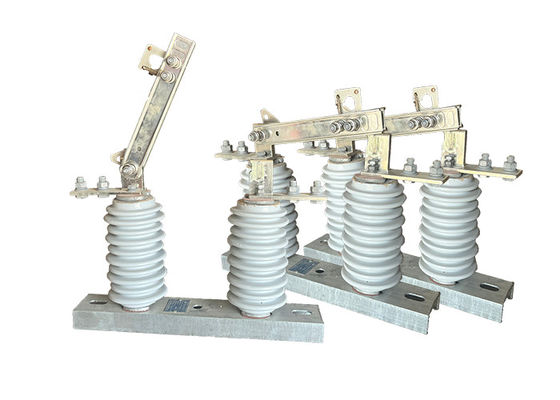

The operation of an outdoor disconnector switch involves a rotating pole that controls the opening and closing of the switch's blade or contact. By rotating the pole, the blade can be engaged or disengaged, thereby connecting or disconnecting the circuit. This mechanism allows for a manual and visible indication of the switch's status.

To ensure operator safety, the pole of the disconnector switch is typically made of a non-conductive material, such as fiberglass or composite materials, which provides insulation against the high voltage present in the system. This insulation protects the operator from electric shock when operating the switch.

Outdoor disconnector switches are available in various designs and sizes to accommodate different voltage and current ratings of the circuits they control. They are commonly mounted on poles or structures in outdoor settings, where they can be easily accessed and operated. In conjunction with other protective devices like circuit breakers and fuses, disconnector switches contribute to the overall safety and reliability of the electrical system by providing a means of isolation and protection.

Feature:

1.Isolation: The switch is used to isolate a single phase of the power system for maintenance or repair purposes.

2.High Voltage Rating: These switches are designed to handle high voltage levels, typically ranging from a few kilovolts to several hundred kilovolts.

3.Manual Operation: The switch is manually operated using a hookstick or a lever. The operator must be trained in the safe operation of the switch.

4.Visual Indicators: Some switches have visual indicators that show whether the switch is open or closed, making it easier for operators to know the status of the circuit.

5.Durability: These switches are designed to withstand harsh environmental conditions, such as extreme temperatures, humidity, and corrosive substances.

6.Safety Features: The switch is designed with safety features to protect operators from electrical hazards, such as insulating materials that prevent accidental contact with live parts.

7.Compact Size: Single-phase high voltage isolator switches are typically compact in size and can be installed in tight spaces.

Condition:

1.The maximum altitude in the specified area does not exceed 1000 meters above sea level. This altitude limitation is relevant for the installation and operation of the equipment.

2.The ambient air temperature has certain limits. The maximum temperature should not exceed +40°C, and the minimum temperature can vary depending on the specific area. In general areas, the minimum temperature should not drop below -30°C, while in Paramos areas, it should not drop below -40°C.

3.The wind pressure should not exceed 700 Pascal (Pa), which corresponds to a wind speed of approximately 34 meters per second. This limit ensures that the equipment can withstand the force exerted by the wind without compromising its functionality or structural integrity.

4.The earthquake intensity should not exceed 8 degrees. This refers to the maximum intensity of seismic activity that the equipment can withstand without being damaged. The specific scale used to measure earthquake intensity may depend on the region or country.

5.The working environment should be free from frequent violent vibrations. This requirement ensures that the equipment remains stable and operational under normal operating conditions. Excessive vibrations can affect the performance and lifespan of the isolator.

6.Ordinary-type isolators should be installed in locations that are kept away from gas, smoke, chemical deposition, salt-spray fog, dust, and other explosive or corrosive substances. These materials can have detrimental effects on the insulation and conduction capabilities of the isolator, potentially compromising its performance and safety.

7.Pollution-proof type isolators are designed for use in areas with severe contamination. However, even in such areas, there should be no presence of explosive substances or materials that can cause fire. This requirement ensures that the isolator remains safe and functional despite the challenging environmental conditions.

Application:

1.Maintenance and Repair: The Loadbuster Electrical Isolator is commonly used to isolate and ground electrical distribution lines for maintenance and repair activities. It allows maintenance personnel to work safely on energized equipment without the risk of electrocution.

2.Emergency Response: The Loadbuster Electrical Isolator can be used in emergency situations, such as power outages or natural disasters, to isolate and ground electrical distribution lines and restore power safely.

3.Switching Operations: The Loadbuster Electrical Isolator can be used to open or close switches and perform other switching operations on electrical distribution lines.

Safety Tips:

1.Compliance with safety standards: High voltage disconnect switches should comply with relevant safety standards, such as IEC, ANSI, or NFPA. Compliance ensures that the switches meet specific safety requirements and have undergone rigorous testing, providing assurance of their reliability and safe operation.

2.Proper ventilation and cooling: Adequate ventilation and cooling systems should be in place for high voltage disconnect switches, especially in enclosed or confined spaces. Proper ventilation helps dissipate heat generated during operation, preventing overheating and reducing the risk of equipment failure or electrical hazards.

3.Hazardous area considerations: High voltage disconnect switches located in hazardous areas, such as those with flammable or explosive atmospheres, should be designed with appropriate protection measures, such as explosion-proof enclosures or intrinsically safe components. These measures mitigate the risk of igniting hazardous substances and ensure safe operation in such environments.

4.Regular inspection and maintenance: High voltage disconnect switches should undergo regular inspection and maintenance to identify and address any potential issues. This includes checking for signs of wear, loose connections, or corrosion, and promptly repairing or replacing any damaged components to maintain the switch's integrity and safety.

5.Clear labeling and signage: High voltage disconnect switches should be clearly labeled with appropriate warning signs and safety instructions. This helps personnel identify the switch, understand its potential hazards, and follow proper safety protocols when operating or working near the equipment.

Technical Parameters:

| Serial No. |

Parameter |

Unit |

Data |

| 1 |

Rated Voltage |

kV |

12 |

| 2 |

Rated Current |

Model No. |

(H)GW9-12(W)/630-20 |

A |

630 |

| (H)GW9-12(W)/1000-20 |

1000 |

| (H)GW9-12(W)/1250-31.5 |

1250 |

| 3 |

4s Short-time withstanding current |

Model No. |

(H)GW9-12(W)/630-20 |

kA |

50 |

| (H)GW9-12(W)/1000-20 |

50 |

| (H)GW9-12(W)/1250-31.5 |

80 |

| 4 |

Rated Insulation Level |

Lightning surge withstand voltage(peak) |

Polar-to-Earth

(Positive & Negative) |

kV |

75 |

Interfracture

(Positive & Negative) |

85 |

Industrial frequency withstand voltage

(1 min)

(Effective value) |

Dry Test/Wet Test |

Polar-to-Earth |

42(Dry)

34(Wet) |

| Interfracture |

48(Dry) |

| 48(Dry) |

48(Dry)

40(Wet) |

| 5 |

Main Circuit Resistance |

μ Ω |

630 |

| 1000 |

| 1250 |

| 6 |

Mechanical Life Time |

times |

50 |

| 50 |

| 80 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!