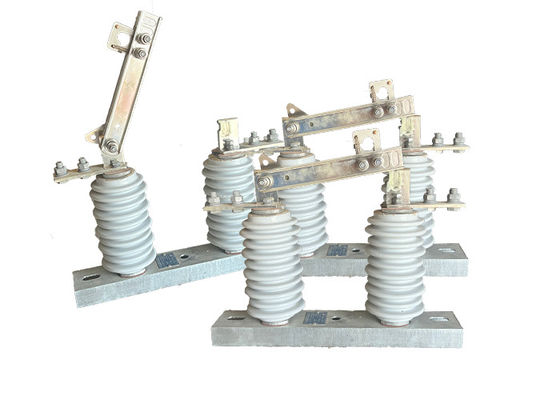

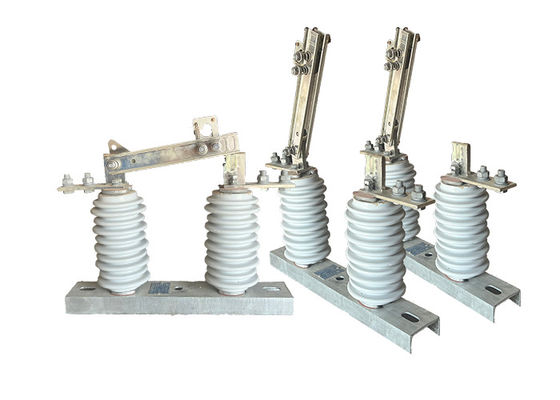

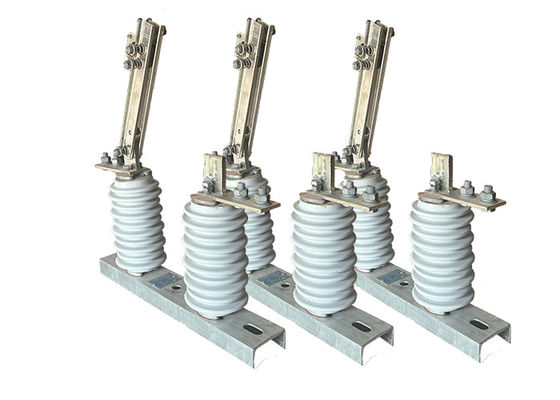

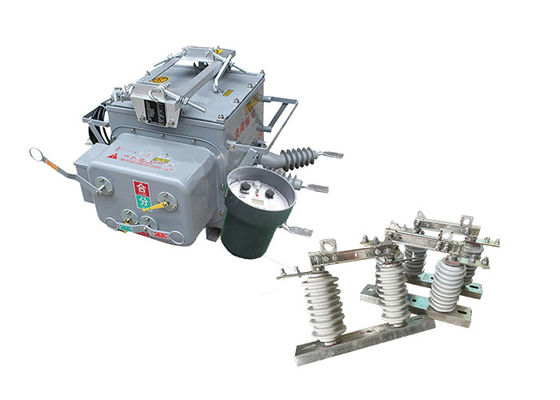

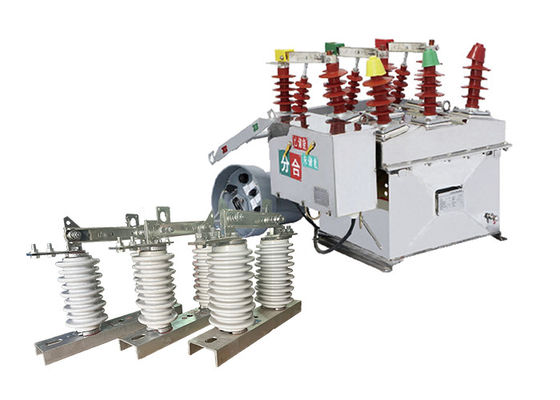

1000A 12kV-36kV Outdoor Electrical Hookstick Disconnector Switch Easy Installation Overhead Line Disconnect Switch

Product Decription:

Outdoor Disconnector Switch is a type of portable tool used in the electrical industry for opening and closing disconnect switches on overhead distribution lines. It is a versatile and lightweight tool that is designed to be operated by a single person, making it easy to use and maneuver.

The electrical hookstick disconnector consists of a telescoping fiberglass pole, which can be extended to reach the disconnect switch, and a set of interchangeable attachments, which allow the user to perform a variety of tasks, such as opening or closing switches and performing visual inspections.

The disconnector is designed to provide a safe and efficient means of opening and closing disconnect switches on overhead distribution lines without the need for manual contact with energized equipment. It is also designed to withstand harsh environmental conditions, such as high winds, rain, and snow, making it suitable for use in outdoor environments.

Structure:

The product being described is composed of a base (plate), post insulator, conductive part, and interlock device. The knife is installed on the dynamic contact knife head through bolts and is separately connected with the static contact head. Each side is maintained in a good contact state by the pressure of the compression spring. The knife is a slot-shaped type, which increases the heat dissipation surface and reduces the temperature rise. This contributes to the mechanical strength of the knife and makes it dynamically thermally stable against short circuits.

The interlocking parts installed at the non-rotating end of the contact knife and the static locking hook on the static contact form the opening locking device. When the brake is closed, the device is self-locking, so the brake knife will not fall off due to its own weight or the action of electric power, which could cause the brake to open without cause.

This product is commonly used in power transmission and distribution systems and plays a crucial role in ensuring the proper functioning of the electrical grid. Proper safety procedures should be followed when working with these switches, and only qualified and trained personnel should be allowed to operate and maintain them.

Operation:

1 Preparation: Before operating the switch, the circuit should be de-energized and properly grounded to prevent any electrical hazards. The switch should be inspected for any signs of damage or wear and tear.

2 Closing the switch: To close the switch, the operator manually or remotely moves the switch handle or control lever to the closed position. This connects the circuit to the power source, allowing current to flow through the circuit.

3 Opening the switch: To open the switch, the operator manually or remotely moves the switch handle or control lever to the open position. This disconnects the circuit from the power source, interrupting the flow of current.

4 Arc management: When the switch is opened, an electrical arc may occur between the contacts, which can be dangerous and cause damage to the switch. To manage the arc, the switch may be equipped with devices such as arc chutes or blowout coils.

5 Safety: Operators of high voltage disconnect switches must follow proper safety procedures to prevent electrical hazards. This may include wearing personal protective equipment, working in teams, and following lockout/tagout procedures.

Feature:

1.High Voltage Rating: High voltage isolator switches are designed to withstand high levels of voltage, typically ranging from several thousand volts to several hundred thousand volts.

2.Robust Construction: High voltage isolator switches are typically made of materials that are highly resistant to electrical arcing, corrosion, and other forms of damage, such as porcelain or polymer.

3.Arc Chutes: Many high voltage isolator switches are designed with arc chutes, which help to dissipate the heat generated by electrical arcing and prevent damage to the switch.

4.Earth Switch: Some high voltage isolator switches are equipped with an earth switch, which provides an additional level of safety by grounding the isolated section of the circuit.

5.Interlocking Mechanism: To prevent accidental closure of the switch while maintenance work is being carried out, many high voltage isolator switches are equipped with an interlocking mechanism that prevents the switch from being closed until all safety procedures have been followed.

6. Visual Indicators: High voltage isolator switches may also include visual indicators, such as lights or flags, that provide a clear indication of whether the switch is in the open or closed position.

Technical Parameters:

| Serial No. |

Parameter |

Unit |

Data |

| 1 |

Rated Voltage |

kV |

12 |

| 2 |

Rated Current |

Model No. |

(H)GW9-12(W)/630-20 |

A |

630 |

| (H)GW9-12(W)/1000-20 |

1000 |

| (H)GW9-12(W)/1250-31.5 |

1250 |

| 3 |

4s Short-time withstanding current |

Model No. |

(H)GW9-12(W)/630-20 |

kA |

50 |

| (H)GW9-12(W)/1000-20 |

50 |

| (H)GW9-12(W)/1250-31.5 |

80 |

| 4 |

Rated Insulation Level |

Lightning surge withstand voltage(peak) |

Polar-to-Earth

(Positive & Negative) |

kV |

75 |

Interfracture

(Positive & Negative) |

85 |

Industrial frequency withstand voltage

(1 min)

(Effective value) |

Dry Test/Wet Test |

Polar-to-Earth |

42(Dry)

34(Wet) |

| Interfracture |

48(Dry) |

| 48(Dry) |

48(Dry)

40(Wet) |

| 5 |

Main Circuit Resistance |

μ Ω |

630 |

| 1000 |

| 1250 |

| 6 |

Mechanical Life Time |

times |

50 |

| 50 |

80

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!