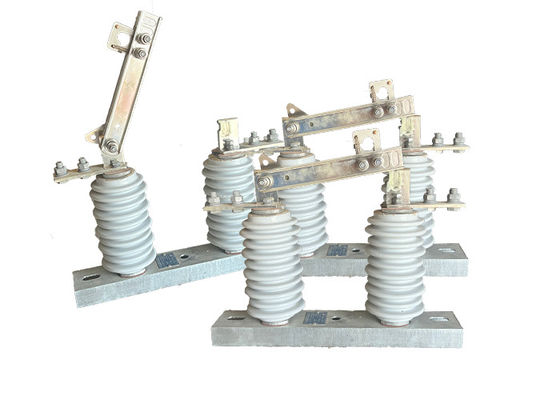

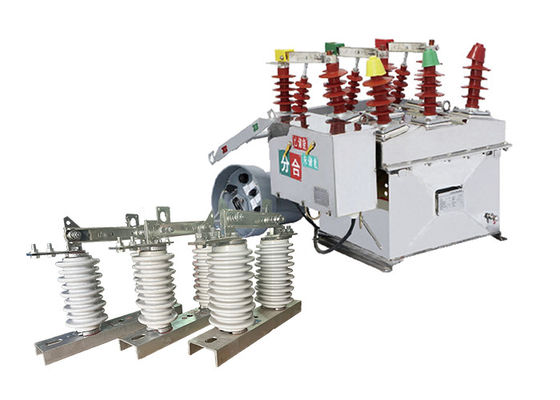

GB/T11022-2011 High Voltage Disconnect Switch Used With Outdoor Vacuum Circuit Breaker For Industrial Substation 1000A

Product Decription:

High voltage disconnect switches are typically used in high voltage transmission and distribution systems to isolate sections of the network for maintenance or repair work. They are also used as a safety device to protect workers from electrical hazards, such as accidental contact with live parts of the system.

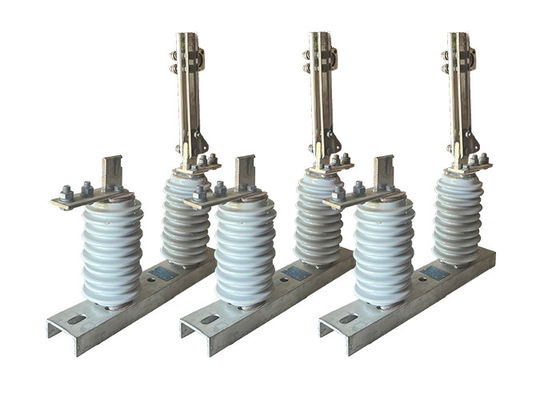

They are designed to handle high voltages and currents, and they are often installed in outdoor locations, where they are exposed to harsh environmental conditions, such as extreme temperatures, wind, rain, and dust. Therefore, they are built to withstand these conditions and are often made of durable materials such as steel or aluminum.

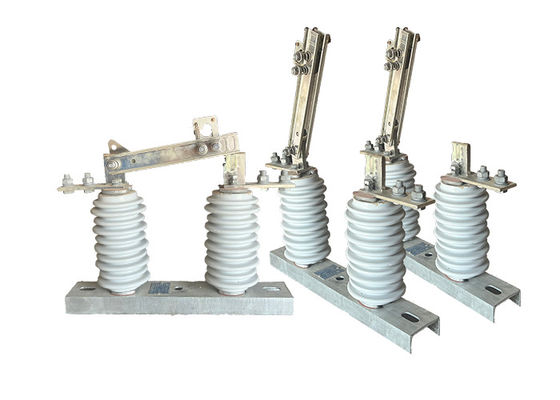

High voltage disconnect switches come in different types and configurations, depending on the specific application and requirements. For example, some disconnect switches are designed for indoor use, while others are suitable for outdoor use. Some are designed to operate manually, while others are automated and can be operated remotely.

In addition to their primary function of isolating circuits, high voltage disconnect switches also have other important features, such as providing a visual indication of their status (open or closed), and ensuring that the circuit is not energized when the isolator is open.

Relation with vacuum ciruit breaker:

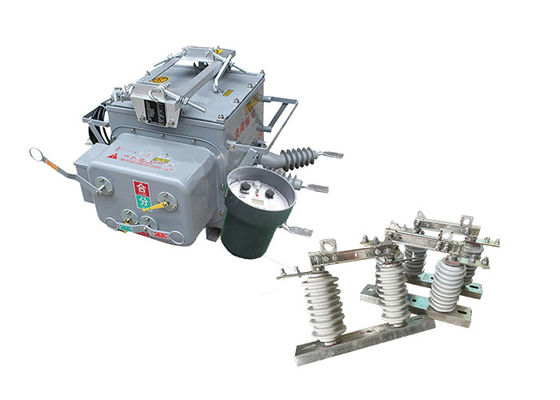

The relation between the outdoor vacuum circuit breaker and the outdoor high-voltage disconnect isolator lies in their complementary roles in the electrical system:

1.Circuit Interruption: The vacuum circuit breaker is responsible for interrupting the electrical circuit during normal operation or in the event of a fault. It acts as the primary means of breaking the current flow. In contrast, the disconnect isolator is used for isolating the circuit from the power source during maintenance or repair activities. It provides an additional layer of safety by physically opening the circuit.

2.Coordination: In high-voltage power systems, the vacuum circuit breaker and the disconnect isolator are often coordinated to work together. The circuit breaker is responsible for detecting faults and tripping to interrupt the current flow, while the disconnect isolator is used to physically isolate the circuit and provide a visible indication of the disconnection.

3.Safety and Maintenance: The disconnect isolator plays a crucial role in ensuring the safety of maintenance personnel. Before any maintenance work can be performed on the electrical equipment, the disconnect isolator is operated to open the circuit and provide a visible air gap. This ensures that the equipment is de-energized and safe to work on. The vacuum circuit breaker, on the other hand, protects the system during normal operation and in the event of faults.

Feature:

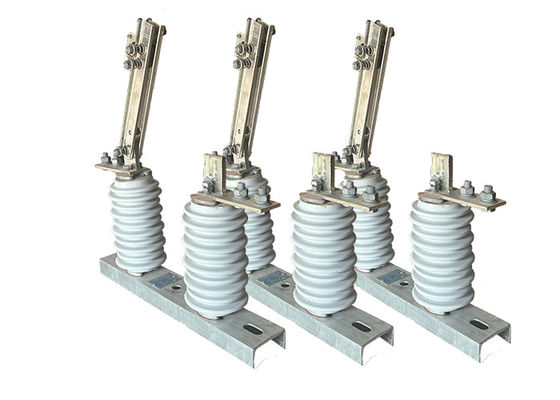

Switchgear Integration: High voltage isolator switches are commonly integrated into switchgear systems, which include other protective devices such as circuit breakers, fuses, and relays. This integration allows for comprehensive control and protection of the high voltage circuit, ensuring safe and efficient operation.

Remote Operation: Many high voltage isolator switches are equipped with remote operation capabilities, allowing them to be controlled from a centralized location. This feature enhances convenience and safety by eliminating the need for manual operation in potentially hazardous environments.

Arc Suppression: High voltage isolator switches are designed to suppress the formation and propagation of electrical arcs when opening or closing the switch. Arc suppression techniques, such as using arc chutes or arc extinguishing chambers, help minimize the risk of damage to the switch and surrounding equipment, as well as reduce the potential for electrical accidents.

Fault Detection: Some high voltage isolator switches are equipped with fault detection mechanisms that can sense abnormal conditions, such as excessive current or voltage, and trigger an automatic switch opening. This capability enhances the overall protection of the circuit by rapidly isolating the faulty section and preventing further damage.

Modularity and Scalability: High voltage isolator switches are often designed to be modular, allowing for easy installation, replacement, or expansion in the electrical system. This modularity enables flexibility and scalability, making it convenient to adapt the system to changing operational requirements.

Application:

1.Maintenance and Repair: The disconnector switch is used to isolate a section of the power line for maintenance or repair purposes. This allows maintenance personnel to work safely without risking electrocution.

2.Load Shedding: In the event of a power overload, the disconnector switch can be used to shed the load and prevent damage to the power line or equipment.

3.Fault Isolation: The disconnector switch can be used to isolate a section of the power line in the event of a fault, such as a short circuit or ground fault. This prevents the fault from spreading to other parts of the network and causing further damage.

4.Switching Operations: The disconnector switch is used for switching operations, such as connecting or disconnecting power sources or rerouting power to different parts of the network.

5.Protection: The disconnector switch is often used in conjunction with other protective devices, such as circuit breakers and fuses, to protect the power line and equipment from damage.

6.Renewable Energy: With the increasing use of renewable energy sources, such as wind and solar, disconnector switches are used to connect and disconnect these sources from the power grid.

Condition:

1.The altitude does not exceed 1000m

2.The ambient air temperature: Maximum+ 40'C ;Minimum:General Area -30'C, Paramos -40 C;

3.The wind pressure does not exceed 700Pa.(corresponding to 34m/s wind speed);

4.The earthquake intensity does not exceed 8 degrees;

5.The working situation is without frequent violent vibration;

6.The installation site of ordinary type isolator should be kept away form gas, smoke chemical deposition, salt-spray fog, dust

and other explosive and corrosive maters that affect seriously insulation and conduction capability of the isolator

7.Pollution-proof type isolator is applies to severe filthy conduction area, however, it shouldn't be any explosive matters and matters causing fire

Technical Parameters:

| Serial No. |

Parameter |

Unit |

Data |

| 1 |

Rated Voltage |

kV |

12 |

| 2 |

Rated Current |

Model No. |

(H)GW9-12(W)/630-20 |

A |

630 |

| (H)GW9-12(W)/1000-20 |

1000 |

| (H)GW9-12(W)/1250-31.5 |

1250 |

| 3 |

4s Short-time withstanding current |

Model No. |

(H)GW9-12(W)/630-20 |

kA |

50 |

| (H)GW9-12(W)/1000-20 |

50 |

| (H)GW9-12(W)/1250-31.5 |

80 |

| 4 |

Rated Insulation Level |

Lightning surge withstand voltage(peak) |

Polar-to-Earth

(Positive & Negative) |

kV |

75 |

Interfracture

(Positive & Negative) |

85 |

Industrial frequency withstand voltage

(1 min)

(Effective value) |

Dry Test/Wet Test |

Polar-to-Earth |

42(Dry)

34(Wet) |

| Interfracture |

48(Dry) |

| 48(Dry) |

48(Dry)

40(Wet) |

| 5 |

Main Circuit Resistance |

μ Ω |

630 |

| 1000 |

| 1250 |

| 6 |

Mechanical Life Time |

times |

50 |

| 50 |

80

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!