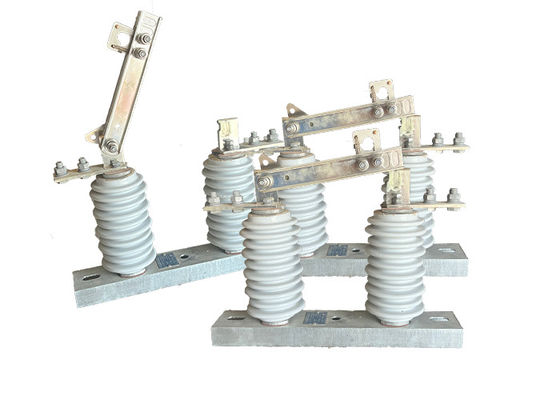

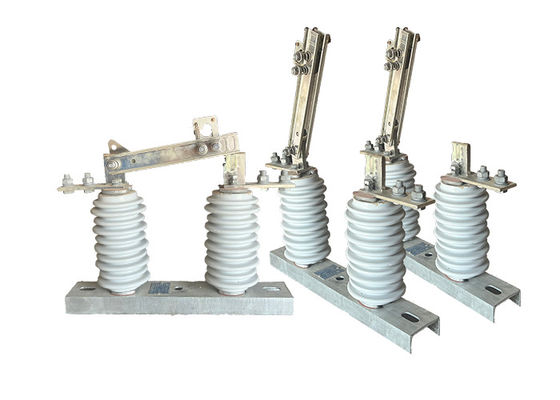

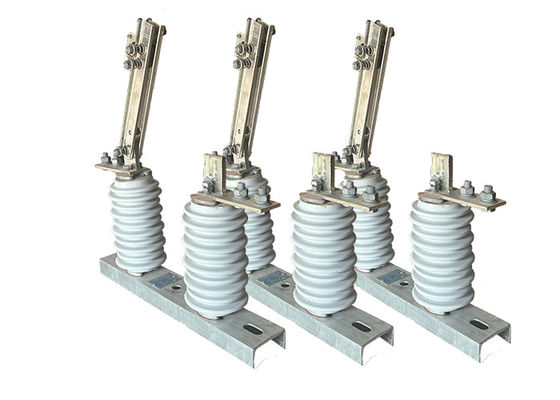

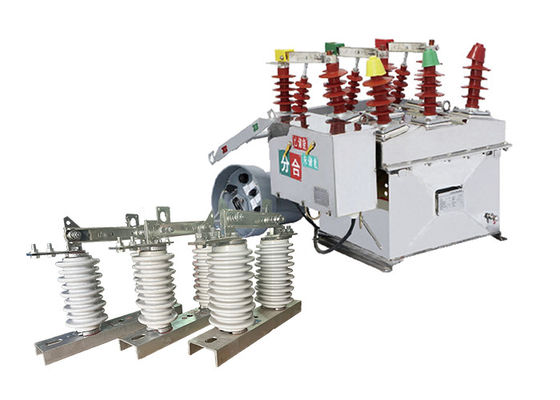

12kV 1000A Portable Hookstick Operated Disconnect Switch Ceramic For Outdoor Substation High Voltage Disconnect Switch

Product Decription:

The high-voltage disconnect switch, also known as an isolator switch, is specifically designed to disconnect or isolate a section of an electrical circuit from its power source. It provides a physical break in the circuit, allowing maintenance personnel to work on the equipment safely without the risk of electric shock. The disconnect isolator does not provide any arc-quenching capabilities like a circuit breaker.

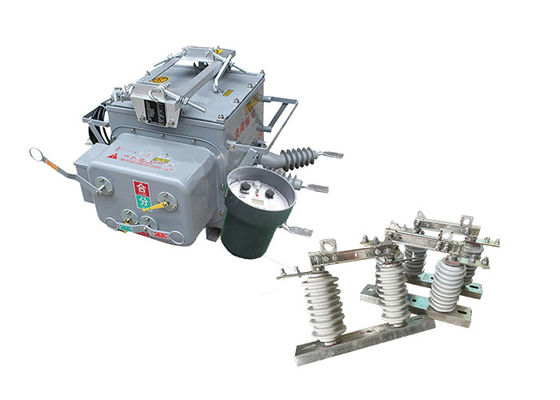

In high-voltage power systems, the high-voltage disconnect switch and the vacuum circuit breake are often coordinated to work together. The circuit breaker is responsible for detecting faults and tripping to interrupt the current flow, while the disconnect isolator is used to physically isolate the circuit and provide a visible indication of the disconnection.

The high-voltage isolator switch plays a crucial role in ensuring the safety of maintenance personnel. Before any maintenance work can be performed on the electrical equipment, the disconnect isolator is operated to open the circuit and provide a visible air gap. This ensures that the equipment is de-energized and safe to work on.

Application:

High voltage disconnect switches are essential components in power transmission and distribution systems, as they allow for the isolation of specific sections of the network for maintenance or repair work. They can also be used to isolate sections of the network in the event of a fault or other abnormal condition.

These switches are designed to handle high voltages and currents, and are typically constructed from durable and robust materials such as stainless steel, aluminum or copper. They are designed to withstand harsh environmental conditions, such as extreme temperatures, high winds, and heavy rainfall.

There are several types of high voltage disconnect switches, including air-break switches, oil-immersed switches, and gas-insulated switches. Air-break switches are the most common type, and they wor k by using a set of contacts that physically separate when the switch is opened. Oil-immersed switches are typically used in high voltage applications and are filled with oil to prevent arcing when the switch is opened. Gas-insulated switches use sulfur hexafluoride gas to insulate the switch contacts, which allows for smaller and more compact switch designs.

High voltage disconnect switches must be operated and maintained by qualified personnel who have received proper training. Safety procedures must be followed when working with these switches, including the use of appropriate personal protective equipment and following lockout/tagout procedures to prevent accidental energization of the equipment. Regular maintenance and testing of high voltage disconnect switches is also important to ensure that they are functioning properly and are safe to use.

Operation:

1.Visual indicators: High voltage disconnect switches may feature visual indicators, such as position indicators or status lights, to provide clear visibility of the switch's status (open or closed). These indicators help operators quickly identify the switch's position and avoid accidental contact with an energized circuit.

2.Interlocking mechanisms: Some high voltage disconnect switches are equipped with interlocking mechanisms that prevent the switch from being opened or closed under certain conditions. For example, a switch may have a mechanical or electrical interlock that requires the circuit to be de-energized before the switch can be operated, enhancing safety.

3.Remote operation: High voltage disconnect switches can be operated remotely using control systems or devices. Remote operation minimizes the need for personnel to be in close proximity to the switch, reducing the risk of electrical hazards and improving operational efficiency.

4.Environmental durability: High voltage disconnect switches are often designed to withstand harsh environmental conditions, such as extreme temperatures, humidity, and corrosive environments. They may feature robust enclosures, sealants, and coatings to ensure reliable operation and longevity in challenging environments.

5.Fault detection and indication: Advanced high voltage disconnect switches may incorporate fault detection and indication mechanisms. These systems can detect abnormal conditions in the circuit, such as overcurrent or short circuits, and provide visual or audible alarms to alert operators of potential issues, facilitating prompt action and minimizing damage.

Structure:

The product being described is composed of a base (plate), post insulator, conductive part, and interlock device. The knife is installed on the dynamic contact knife head through bolts and is separately connected with the static contact head. Each side is maintained in a good contact state by the pressure of the compression spring. The knife is a slot-shaped type, which increases the heat dissipation surface and reduces the temperature rise. This contributes to the mechanical strength of the knife and makes it dynamically thermally stable against short circuits.

The interlocking parts installed at the non-rotating end of the contact knife and the static locking hook on the static contact form the opening locking device. When the brake is closed, the device is self-locking, so the brake knife will not fall off due to its own weight or the action of electric power, which could cause the brake to open without cause.

This product is commonly used in power transmission and distribution systems and plays a crucial role in ensuring the proper functioning of the electrical grid. Proper safety procedures should be followed when working with these switches, and only qualified and trained personnel should be allowed to operate and maintain them.

Safety Tips:

1.Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and flame-resistant clothing.

Before working on the switch, ensure that the power supply is turned off, and the switch is properly grounded.

2.Follow the manufacturer's instructions for operating the switch, and do not attempt to bypass safety features or use the switch for purposes other than its intended use.

3.When working on the switch, use insulated tools and equipment to prevent electric shock.

4.Avoid touching any conductive parts of the switch and keep a safe distance from the switch when it is in operation.

5.Never attempt to repair or modify the switch yourself unless you are a qualified and trained professional.

6.Keep the area around the switch clean and free of debris that may interfere with its operation.

7.Regularly inspect the switch for signs of wear or damage, and replace any damaged or worn parts as soon as possible.

8.Only authorized personnel should be allowed to operate or perform maintenance on the switch.

9.In case of an emergency, follow established emergency procedures and shut off power to the switch immediately.

Technical Parameters:

| Serial No. |

Parameter |

Unit |

Data |

| 1 |

Rated Voltage |

kV |

12 |

| 2 |

Rated Current |

Model No. |

(H)GW9-12(W)/630-20 |

A |

630 |

| (H)GW9-12(W)/1000-20 |

1000 |

| (H)GW9-12(W)/1250-31.5 |

1250 |

| 3 |

4s Short-time withstanding current |

Model No. |

(H)GW9-12(W)/630-20 |

kA |

50 |

| (H)GW9-12(W)/1000-20 |

50 |

| (H)GW9-12(W)/1250-31.5 |

80 |

| 4 |

Rated Insulation Level |

Lightning surge withstand voltage(peak) |

Polar-to-Earth

(Positive & Negative) |

kV |

75 |

Interfracture

(Positive & Negative) |

85 |

Industrial frequency withstand voltage

(1 min)

(Effective value) |

Dry Test/Wet Test |

Polar-to-Earth |

42(Dry)

34(Wet) |

| Interfracture |

48(Dry) |

| 48(Dry) |

48(Dry)

40(Wet) |

| 5 |

Main Circuit Resistance |

μ Ω |

630 |

| 1000 |

| 1250 |

| 6 |

Mechanical Life Time |

times |

50 |

| 50 |

80

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!