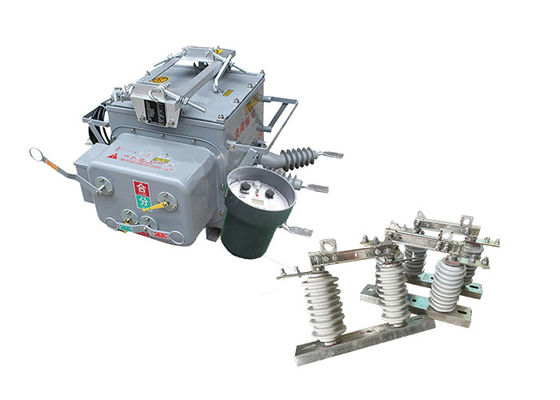

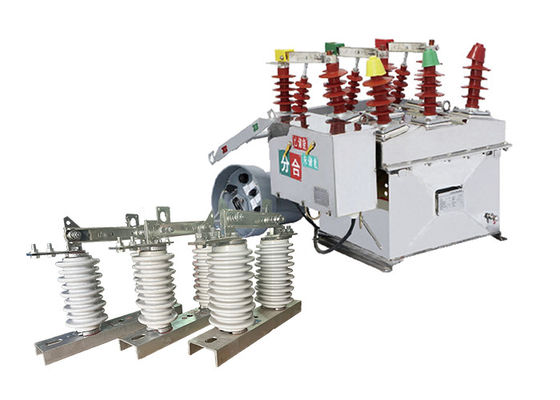

Automatic Recloser Electrical Sectionalizer High Voltage 630A Vacuum Circuit Breaker With IntelligentController

Product Description:

The ZW32-12(F) automatic recloser electrical sectionlizer is specifically designed for outdoor environments. It features enhanced durability and weather resistance, allowing it to withstand various harsh weather conditions such as rain, humidity, and extreme temperatures. This ensures reliable operation and longevity in outdoor installations.

It is capable of effectively breaking and closing load currents, overload currents, and short circuit currents in electronic systems. It provides reliable interruption and switching operations, ensuring the safety and proper functioning of the electrical system.

In addition to substations, the ZW32-12 vacuum circuit breaker finds extensive application in industrial and mining enterprises. It offers reliable protection and control in the distribution systems of these facilities, safeguarding motors, transformers, and other electrical equipment from overcurrents and short circuits. This contributes to maintaining a stable and secure power supply in industrial and mining operations.

It is specifically designed to handle frequent operations in rural power grids. It serves as a sectional switch, allowing for efficient segmentation of the power grid. When equipped with a controller, it enables distribution network automation, improving the reliability and efficiency of the rural power system.

With the installation of a controller, the ZW32-12 automatic recloser electrical sectionlizer can seamlessly integrate into power grid operations. It enables remote monitoring, control, and automation of the distribution network, optimizing system performance and facilitating efficient energy management.

Controller Introduction:

The ZW32-12(F) automatic recloser electrical sectionlizer is equipped with a 485/232 communication interface, allowing for seamless integration into monitoring systems. It can also be connected through optical fiber or wireless communication for remote monitoring. This enables real-time monitoring of the circuit breaker's status, performance, and fault conditions, facilitating proactive maintenance and efficient troubleshooting.

In the event of a permanent fault, the ZW32-12(F) automatic recloser electrical sectionlizer features an automatic acceleration tripping function. This means that if the fault persists after reclosing, the circuit breaker will automatically trip with increased speed, providing enhanced protection against persistent faults and minimizing potential damage to the system.

It allows for adjustment of the reclosing delay time. This feature provides flexibility in configuring the reclosing operation based on the specific requirements of the power system. It enables customization to optimize the system's response to different fault scenarios and improve overall system reliability.

The ZW32-12(F) automatic recloser electrical sectionlizer incorporates an anti-misoperation design for the jump closing circuit. This design prevents accidental or unintended closure of the circuit breaker. Additionally, it includes an anti-jump function, which ensures that the circuit breaker remains in a stable closed position, reducing the risk of sudden tripping due to external factors.

It is equipped with the ability to distinguish between in-zone and out-of-zone faults using zero-sequence current analysis. This allows for accurate fault discrimination, enabling faster and more precise fault isolation and minimizing the impact on the power system.

The ZW32-12 circuit breaker incorporates a remote control switch with a specific design to prevent misoperations. This feature ensures that remote operations are carried out safely and reduces the risk of accidental tripping or unintended actions.

Application:

1.Substations: It is commonly used in both indoor and outdoor substations for protection and control of medium-voltage power distribution. The vacuum circuit breaker ensures reliable interruption of fault currents, overload currents, and load currents, safeguarding the substation equipment.

2.Industrial and mining enterprises: The ZW32-12 vacuum circuit breaker is employed in the distribution systems of industrial and mining enterprises to protect motors, transformers, and other electrical equipment from overcurrents and short circuits. It helps maintain the stability and safety of the power supply in these facilities.

3.Rural power grids: Due to its ability to withstand frequent operations, the vacuum circuit breaker is suitable for application in rural power grids. It can be used as a sectional switch, allowing for efficient segmentation of the power grid. Additionally, when equipped with a controller, it enables automation of the distribution network, improving the reliability and efficiency of the rural power system.

4.Commercial buildings: The vacuum circuit breaker is also utilized in commercial buildings for power distribution and protection. It ensures safe and reliable operation of electrical systems, preventing damage to equipment and minimizing downtime.

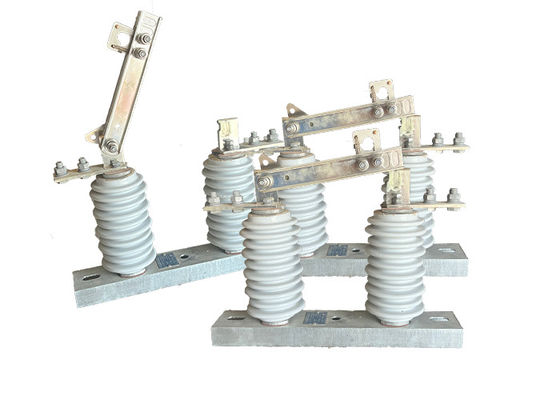

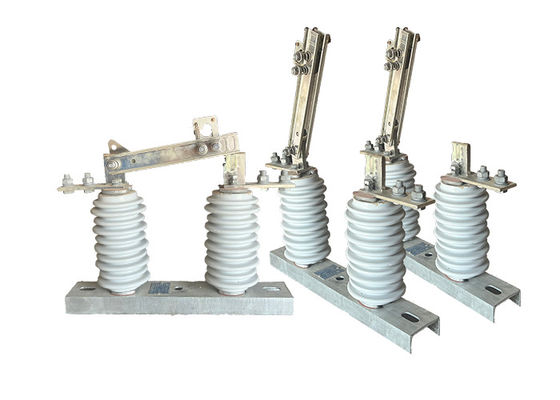

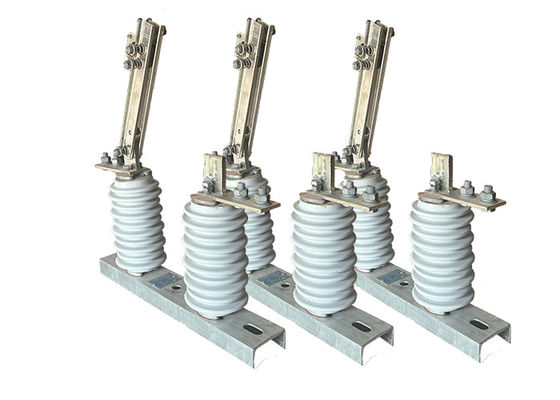

Structure:

The load break switch is composed of pillar, base and suspensions for mounting, fixing and lifting.

1. The column high voltage load break switch equipped with vacuum interrupter has stable and reliable breaking performance, no ignition and explosion hazard, safety, maintenance-free, small size, light weight and long service life, etc.

Features.

2. The load break switch is fully enclosed, with good tightness, moisture proof and dehumidifying. It is suitable for use in hot and humid zone.

3. The closing and opening of the load break switch can be operated manually or electrically or remotely.

4. The operating mechanism is novel, simple, reliable, small size, mechanical life up to 10,000 times, the energy storage motor is a DC permanent magnet motor, the voltage level is -220V-110V-48V-24V which can be choose.

Advantage:

1.Small Size: The device is designed with a compact form factor, allowing for easy installation in limited space environments. Its small size makes it suitable for applications where space is a constraint.

2.Light Weight: The device is lightweight, which simplifies transportation and installation. It reduces the physical burden during handling and makes it easier to mount or integrate into existing systems.

3.Maintenance-Free: The device is designed to require minimal maintenance. It is built with durable components and optimized for long-term reliability, reducing the need for frequent inspections or replacements. This feature saves time and resources on maintenance activities.

4.Anti-Condensation: The device incorporates measures to prevent condensation. It includes protective features such as sealing or insulation to minimize the risk of moisture build-up. This helps maintain optimal performance and protects internal components from potential damage caused by moisture.

5.Adapts to Adverse Weather Conditions and Dirty Environment: The device is designed to withstand challenging weather conditions, such as extreme temperatures, humidity, or exposure to dust and dirt. Its robust construction and protective features ensure reliable operation in adverse environments, reducing the risk of malfunctions or performance degradation.

Technical Parameter:

| Serial No. |

Parameter |

Unit |

Data |

| 1 |

Rated voltage |

kV |

12 |

| 2 |

Insulation level of Fracture |

Working Frequency(Dry Test/Wet Test) |

48 |

| Voltage of Lightning Shock Test (Peak) |

85 |

| 3 |

Level of Insulation to ground/phase to phase |

Working Frequency |

Dry Test |

42 |

| Wet Test |

34 |

| Voltage of Lightning Shock Test (Peak) |

75 |

| 4 |

Rated Current |

A |

630 |

| 5 |

Rated thermal stability current (Effective value) |

kA |

20 |

| 6 |

Rated short-circuit breaking current (Effective value) |

25 |

| 7 |

Rated thermal stability time |

s |

4 |

| 8 |

Rated short-circuit closing current(Peak) |

kA |

63 |

| 9 |

Rated dynamic stability current (Peak) |

| 10 |

Mechanical lifetime |

times |

10000 |

| 11 |

Opening rated current |

1000 |

| 12 |

Surrounding air temperature |

Highest Temperature |

℃ |

-55 |

| Lowest Temperature |

+60 |

| Difference ofMaximum daily temperature |

K |

≤25 |

| 13 |

Altitude |

m |

≤2500 |

| 14 |

Humidity |

Average of daily relative humidity |

% |

≤95 |

| Average of monthly relative humidity |

≤90 |

| 15 |

Earthquake-resistant capacity |

Horizontal acceleration |

g |

0.25 |

| Ground vertical acceleration |

0.125 |

| Safety Factor |

/ |

1.67 |

| 16 |

Wind Speed |

m/s |

≤35 |

| 17 |

Ice Thickness |

mm |

≤20 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!